H76 | Session BILTEur 2019

- Damien Lefranc

- 27 oct. 2019

- 9 min de lecture

Dernière mise à jour : 2 janv. 2021

Pour la troisième année consécutive, je participais et assistais aux conférences BILT de la zone Europe. Ce regroupement de passionnés de BIM et de nouvelles technologies s'est réuni cette année à Edimbourg en Ecosse. A cette occasion, je présentais pendant 75 minutes en anglais, une nouvelle étude de cas issue du projet H76, conçu, construit et maintenu par le Groupe Legendre. Retour sur cette présentation.

Handout :

Session 3.3 : H76 Headquarter : IoT and BIM Dynamic

Class description

The new case study of the H76 headquarter is an opportunity to understand the BIM dynamic approach developed by Legendre Construction. The challenge is to connect the IoT to models from the design phase to the O&M phase through existing and new technologies. This process will put users at the centre of the model lifecycle thanks to the BIM.

About the Speaker – Damien Lefranc

Graduate in construction engineering at ESITC Caen, I started my working life in a SME company as an apprentice. I realized a project, at the end of my studies, about BIM Interoperability. I’m interested in digital and construction since the beginning of my high school studies. I discovered the BIM approach in Denmark at VIA University College during my 4th year in engineering school. I join Groupe Legendre in December 2014. It was originally a family-run SME. Now, it is a major construction, real estate and energy group, both nationally and internationally. I’m also teaching in engineering school about BIM management for Revit users and Dynamo users. For me, BILT event, it’s an opportunity to present a case study which use digital models, BIM innovation, collaboration, VR and so on…

About the co-worker of this project – Pierre Morel

Shortly graduate in construction engineering at INSA Rennes, I am carrying on architecture studies in a double degree at ENSAB (Brittany National School of Architecture). I discovered the BIM expertise during Damien Lefranc courses. I had worked several months in internship whim him at Legendre Construction to match ArchiCAD interoperability operation phase. Thus, I wish to continue as an architect to bring my technical skills to organize architectural models.

In brief

This is my third participation in BILT EUR (after Aarhus in 2017 and Ljubljana in 2018) and, like every year, I will introduce a comprehensive case study. For the audience, this presentation is an opportunity to talk about the BIM set up with the design team, on construction site and to give answers to the real problems of the client in the long term. Currently, it’s the most advanced and innovative project in BIM approach for Legendre Construction. We will focus on this objective: how to deliver an as-built model which run into a BIM dynamic software or platform.

In Aarhus in 2017, I told you about the Parker Tower project in London. The tower was been refurbished in Covent Garden. Today, the handover is done. Several fields of BIM approach were mentioned but the logistics, the model breakdown and planning in BIM was put forward. These kinds of BIM approach were hardly introduced at BILT event. Nevertheless, this is the first skill we developed in Preconstruction team in Legendre Construction. In Ljubljana in 2018, I spoke about the Avril Campus in Rennes. The campus, composed of offices and a corporate restaurant, was the opportunity to explain our BIM coordination process in Preconstruction team. Our vision of VR and real-time rendering was been clarified too.

In Edinburgh in a few days, I will present you the future of IoT and BIM dynamic in Groupe Legendre.

Biography of the Preconstruction team

For five years, the preconstruction team of Legendre Construction establishes BIM expertise about model design, model coordination, logistic and model breakdown, VR and AR. Since this year, we have a new skill with the expertise of operations and maintenance in open BIM with IFC and BCF. In my case, I worked on these various fields since the beginning of my career at Legendre Construction. So, I had a central responsibility for the interoperability in this project. Having no expertise in ArchiCAD, I hired a student of architecture for 6 months. He was a great help to me and to assist the design team.

H76 project presentation

who they are ?

Habitat 76 is the biggest social lessor of Seine Maritime (Normandie) with more than 28000 residentials buildings in 190 cities. In France, this organization has a high requirement in BIM approach. The BIM protocol of Habitat 76 relate to offer support to investment decisions by comparing functionality, scope, environmental criteria and project costs; to improved quality assurance and feasibility; to make effective use of the data of the building project during construction, operations and maintenance. Currently, this public authority uses Abyla software to exchange data in BIM standard and to maintain its residential real estate.

The project: H76 Headquarter and two residential buildings

The project includes the future headquarter of Habitat 76 and two social housings for 67 apartments in total. Legendre construction won the deal to design, to build and to maintain the both types of edifice. Among these 3 buildings, the occupants – employees for one and the tenants for the others 2 – will be able to interact with the maintenance operator thanks to the BIM dynamic and IoT. Therefore, we had must provide a means of data exchange.

The design allows walking between these building. There is a large sunlight in the middle of parcel which is a value for the future environmental label such as “passivhaus”. The headquarter consists of 10 storeys with mainly L shapes and residential buildings consist of respectively 8 storeys for housing n°1 and 6 storeys for housing n°2. All buildings are erected on the top of a parking lot. Due to the shape, the buildings have a refined and simple appearance in order to have ease of operation and maintenance.

For the headquarter, the main objective had to provide as-built models in open BIM to stock data and to use it in the BIM dynamic platform. For the residential buildings, the main objective had to provide as built models in open BIM to stock data, to use it in the BIM dynamic platform and to use it in Abyla.

MaXim synopsis

MaXim will be an assets management cross-platform made by Legendre Construction. It may be run in a tablet, mobile and PC. With these very ambitious claims of the client, Legendre Engineering wants to promote its own cloud platform in BIM with IFC and BCF formats. The Habitat 76’s specifications were as follows:

Allow to visualize IFC models by discipline;

Allow to do a collaborative maintenance;

Allow to do an energetic maintenance;

Allow to use IoT;

Allow to have access for services like booking a meeting room.

Based on BIMsync, MaXim will use Uniformat II classification to connect models with objects. Codes will be implemented in a specific property sets to the objects with the various software. My job was to sustain the IFC models and IFC objects with Uniformat II code in IfcTypeProduct for the MaXim’s developer. MaXim will be multi-site platform in order to have a global vision about all future projects. The dashboard will show the energy consumption, the requests for maintenance and documents.

Abyla synopsis

Abyla is a real estate management software using BIM approach. Its aims are to centralize and to organize data, to investigate database, to manage and operate the real estate, to communicate and share intelligent graphs on the web, to control and regulate funds. Habitat 76 manages all social real estate by means of this solution. The singularity of this software is to classify BIM objects according to their type names. In this case, we don’t use a BIM classification such as COBie, Uniformat or OmniClass. The code will be recognized by a list of type name and it will be implemented with Abyla. My work was to sustain the IFC models and IFC objects with the correct type names of IfcTypeProduct.

The design team

For the first part of the project, the design team was comprised of 2 architecture agencies (AIA life designers for the headquarter and Atelier Bettinger Desplanques for housings), 2 MEP design firms (BE Echos for mechanical and plumbing models and BIELEC for electrical models) and Legendre Construction for the BIM management and the design of Structure model. Except for the Preconstruction team, the design team were beginners in BIM. They needed a lot of help to manage their digital models.

Digitals models

Several software had to allow a BIM interoperability. I provided my Revit expertise and Pierre Morel provided his own with ArchiCAD.

Classification

We had a common aim between my teammates in Preconstruction: set the Uniformat II code in IfcClassification parameter. This common IFC property set parameter is a label. In Revit, the way to achieve was simple with a new shared parameter. During this presentation, I will show you how I have made its implementation reliable with Dynamo. In ArchiCAD, the integration was a bit different. I will show you how we used the IFC translator and the IFC project manager for the Uniformat II code implementation. To go further, we had to do a quality check of models. That is to say, we checked if the code was correct in IFC format with Solibri and in RVT format with Dynamo.

The Abyla code is defined by the software and not by a specific classification. This code is a result of type name. So, we have established a process to control the type name of object to compare a list provided by Labeo (Abyla firm). The Abyla code may integrate in a shared parameter which is empty during the design and construction phases

BIM Management by Preconstruction team

To the beginning of the project, I wrote a BIM execution plan (BEP) or BIM Convention in accordance with BIM guidelines of PROBIM. This pre-contract BEP was an evolutive document. Now, the post-contract BEP is composed of:

Employers information requirements;

BIM management documents

Fields of BIM applications;

Interoperability procedure;

Quality check and BIM coordination process;

IFC and RVT deliverables

Common rules of design;

BIM dynamic requirements;

Quickly, I transfered lot of configuration files like Xml, Json, txt to organize the IFC mapping, Pset and shared parameters in a various softwares..

Because it’s a flagship project for Legendre Construction, we wrote several appendixes that we will use in future projects in open BIM.

First of all, I studied the meaning of create the IfcSpace and IfcZone in Revit. Then, I described the Uniformat II code implementation and to finish I outlined the way of IFC standardization in Revit. These 3 documents shared for H76 project and they will share in future BIM management projects into a Revit Starter Pack (zip file). The same appendices were drafted to help ArchiCAD users and will share into an ArchiCAD Starter Pack. Moreover, the level of Development appendix allowed to control the level of information and the geometry level for all objects.

BIM Coordination by Preconstruction team

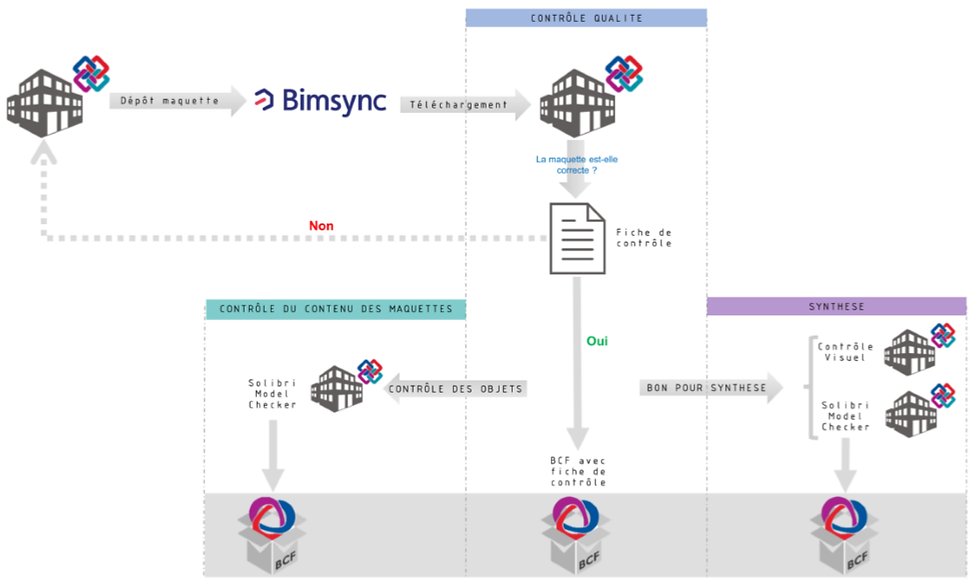

One part of the Preconstruction team involves controlling models and give a BIM coordination advice through the issues. Raphael and Lydia, my coordination teammates, used Solibri to create rules for quality check about:

Model by discipline (structure, architecture, MEP and site models);

LODs (geometry and level of information) of objects;

Coordination between models.

These 3 kinds of issues created BCF files and the coordination team shared them on the collaborative platform named BIMsync. PROBIM, the client assistant, worked in a same way with BCF. We were able to organize issues by issues board list (quality check for housing, quality check for headquarter, BIM coordination, PROBIM Issues).

MaXim by Legendre Construction

How could define the BIM Dynamic?

If the BIM is now becoming widespread in the design and construction of buildings, what becomes the digital model once the book delivered? How to make it live?

BIM dynamic starts when the building is commissioned. Throughout his life, his digital twin will be updated after each maintenance or physical or functional space rework. To do this, the structuring of data related to operation and maintenance must be defined as far upstream as possible when designing the digital model, and this, around a “Common Data Environment” (CDE). This digital avatar should not be simply composed of an extraction of the digital mock-up of the works executed, but of all the documents and graphic pieces composing the folder of the executed works.

Once the Digital Model of Exploitation finalized and consolidated, it integrates construction data, equipment, space, energy capacity and consumption… but also the life cycle of the elements composing the building.

This method allows:

To have access to all the data of the building as built;

To plan the periodic maintenance and to intervene during an incident;

To control the costs related to the maintenance and degradation of materials and thus create a multi-annual building plan;

To control and manage energy consumption;

From supervisor the management of spaces and people;

Remote control of the equipment for a better quality of life and comfort of the occupants.

Connecting models with IoT

Thanks to the connected equipment present today, in the buildings, whether through the “Centralized Technical Management” (CTM) or the “Internet of Things” (IoT), the connection with the digital model becomes possible. Indeed, the communication protocols of objects and equipment based on standards can connect various software including some BIM viewer. The application programming interfaces (APIs) of these different solutions can communicate with each other. This is why Groupe Legendre has decided to create a multi-business platform linking the digital moch-up to the connected objects present on the sites in operation. Welcom to MaXim !

Link between users and O&M supervisor

MaXim is not a supervisor for technicians but an interface created for users and managers of buildings. Our philosophy is to place the occupants in the role of major of life of the space which it occupies, that it is at its place of work or in its lodging.

The platform becomes the central core establishing objective links between the digital model and the documents that compose it, maintenance management software (CMMS), energy management, equipment management and functional spaces. Each software connected to MaXim works independently and the technicians continue to work as usual. Only information revolves around our software, they are captured to display the user only the data that interests him. Thus, a conventional user can issue requests for interventions following an incident, control its consumption or even control the equipment of a dedicated space, while a manager can have a global view of energy consumption of buildings and preventive maintenance to come as well as the ability to drive floors or entire areas.

Presentation :

Commentaires